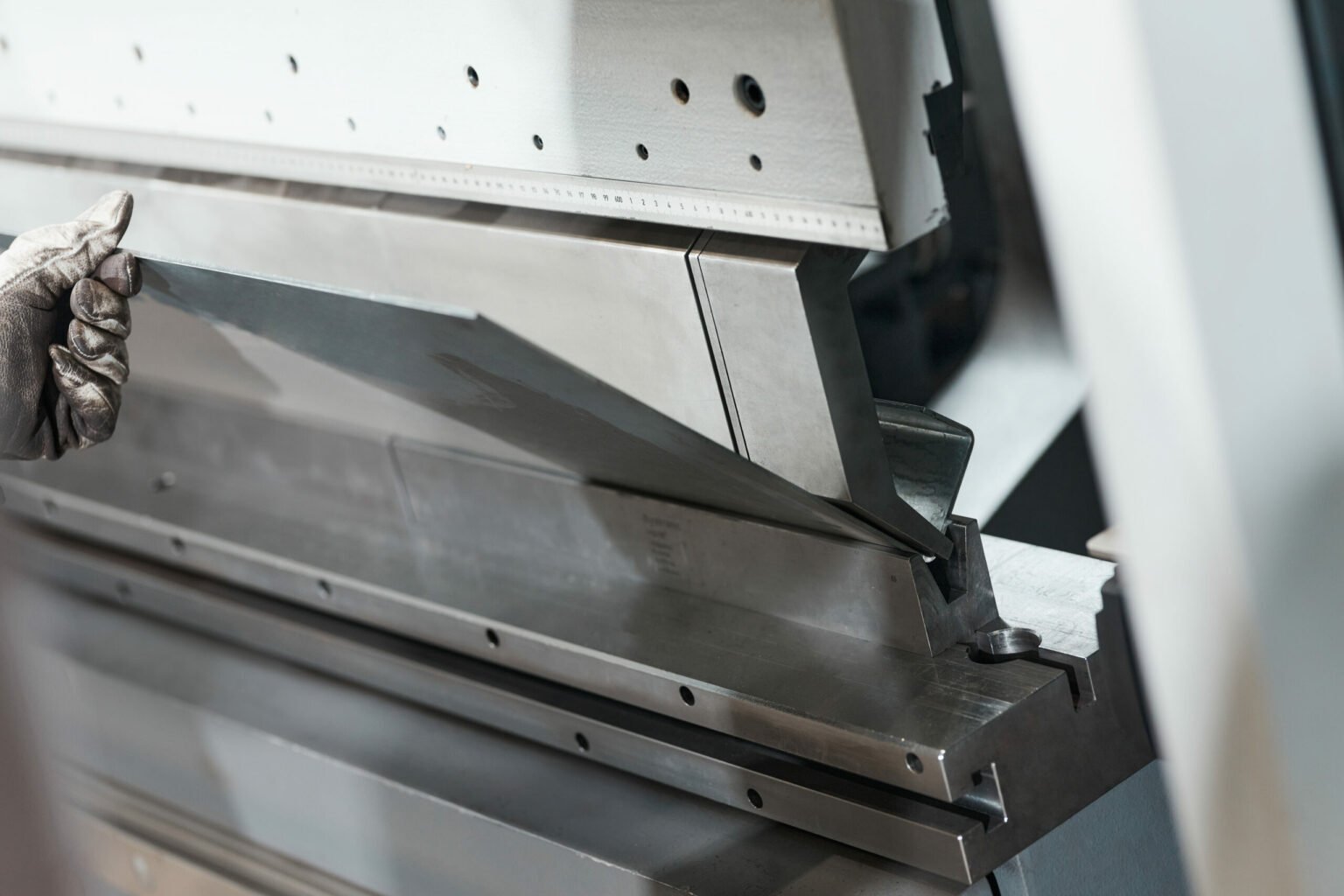

SHEET METAL BENDING

Sheet metal bending allows us to shape and form various materials into the desired shape and angle. In our production, we utilize two state-of-the-art bending machines: BYSTRONIC XPERT 500/6200 and BYSTRONIC XPERT 80/1530.

Whether your project requires intricate bends for smaller components or bending of large-scale materials, our machines provide precision and efficiency.

With the capability to process a wide range of materials and thicknesses, we can offer versatile solutions tailored to the specifics of your project, be it in the automotive industry, construction, or many other industries.

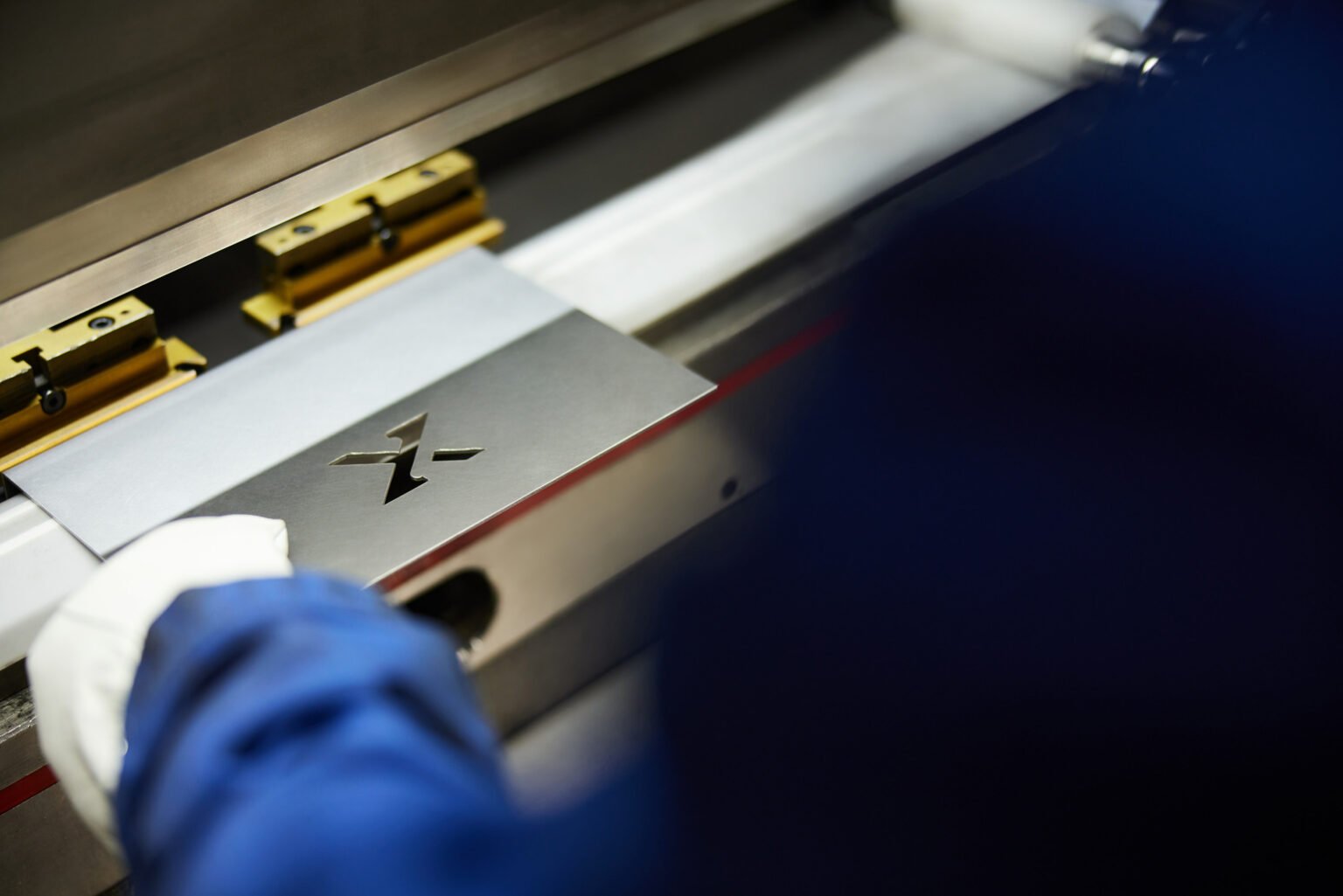

BYSTRONIC XPERT 500/6200

- Maximum bending force: 500 t

- Maximum length of detail: 6200 mm

BYSTRONIC XPERT 80/1530

- Maximum bending force: 80 t

- Maximum length of detail: 1530 mm

OTHER SHEET METAL PROCESSING SERVICES

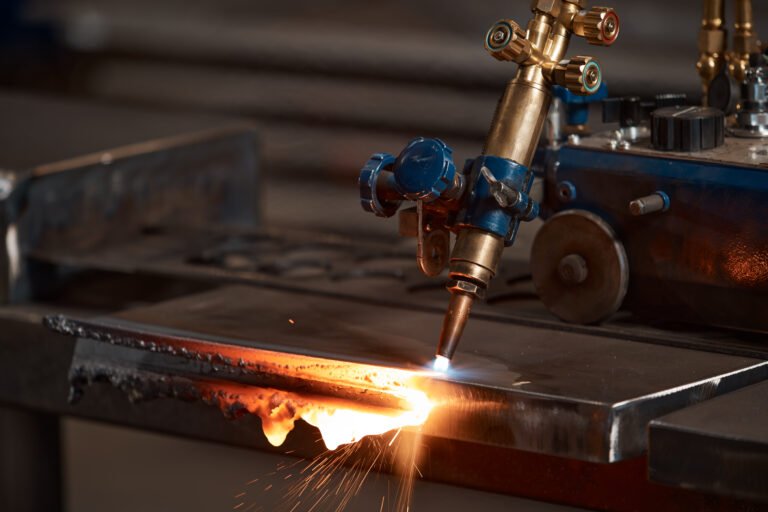

PLASMA AND GAS CUTTING

Our two Microstep CNC drilling and cutting machines for plasma and gas cutting offer fast and precise cuts for various types and thicknesses of metal.

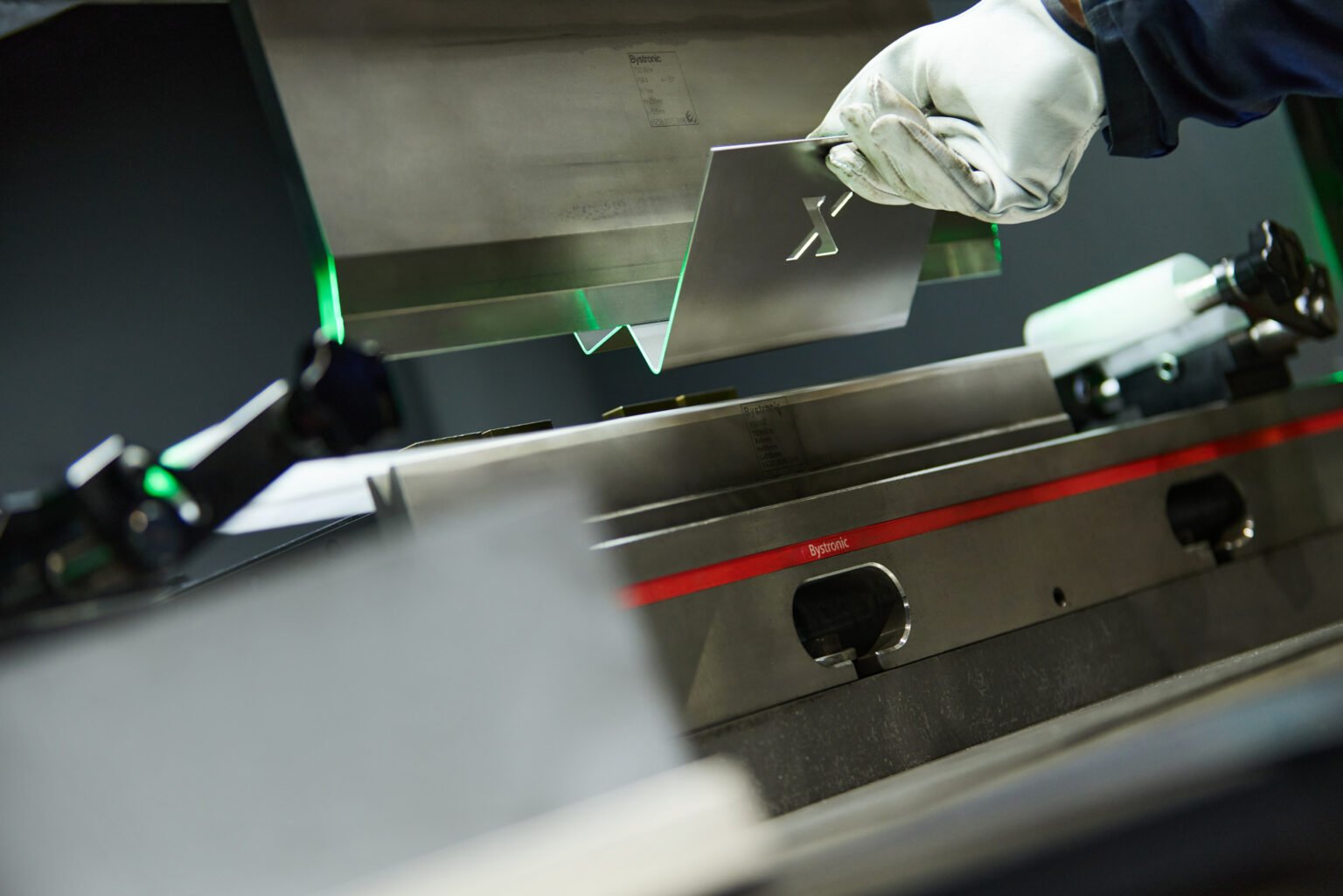

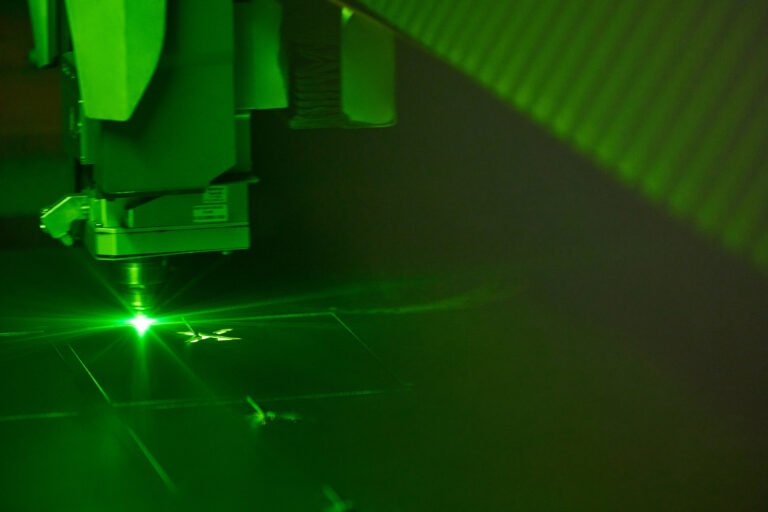

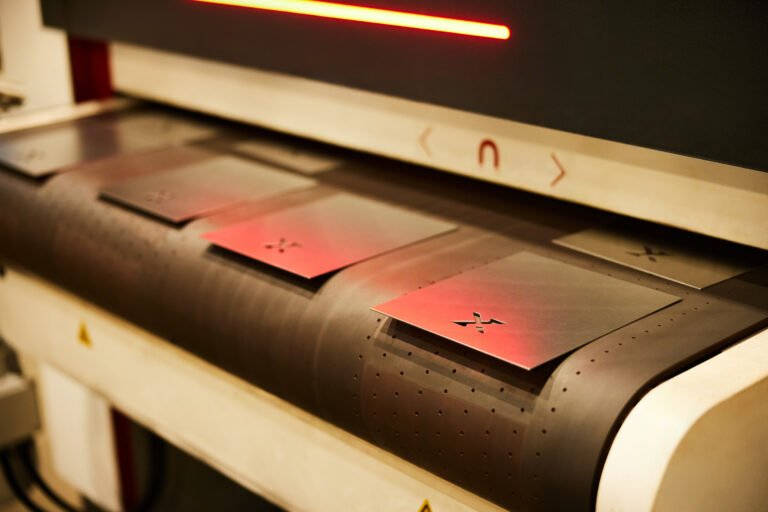

LASER CUTTING

Our two laser cutting machines are equipped with 12 and 20 kW fiber lasers, enabling efficient and precise cutting of different materials and thicknesses.

EDGE PROCESSING

The TIMESAVERS Series 42 machine allows for effortless deburring of sharp edges on sheet metal parts, cleaning of cutting edges, and achieving rounded edges that meet the highest industry standards.

Chamfering

We perform chamfering according to the preparation requirements of both sheet metal parts and profiles. Proper chamfering of these parts ensures the quality, strength, and durability of the welds.

SHOT BLASTING

Shot blasting is a surface treatment process that removes rust, paint, or other impurities from metal and ensures surface roughness for subsequent processing or coating.

MARKING AND PACKAGING

Whether it's a large-scale construction project or complex manufacturing requirements, our marking services guarantee clear labeling for each product, simplifying production management seamlessly.

FEEL FREE TO CONTACT US!

JANAR VARBOLA

SALES TEAM LEADER FOR STEEL SERVICES

If you have a question, I have an answer! I help with all questions about sheet and profile processing. All inquiries will arrive in my mailbox, and I will answer them as soon as possible, but no later than two working days.