CNC PROFILE PROCESSING

KALTENBACH

The Kaltenbach profile processing machine offers several significant advantages to clients in the construction and machinery industries, including excellent cutting performance, precision, and cost savings.

Equipped with carbide saw blades, the machine can cut various types of steel profiles, ranging from 1000 × 500 mm (maximum) to 50 × 5 mm (minimum), while achieving higher cutting performance. Through automated functions, the machine optimizes the cutting process, enhancing overall efficiency and ensuring rapid project completion and timely delivery.

For profile drilling, the machine utilizes carbide and interchangeable tip drills ranging in size from 6 to 40 mm, as well as milling for larger holes and oval-shaped openings. Kaltenbach enables processing of large and complex profiles up to 16 meters in length in one piece. With capabilities for cutting, drilling, and even creating oval holes, we provide a comprehensive solution for steel profile processing needs.

The Kaltenbach profile processing machine supports various file formats, including .nc, .nc1, .stp, and .step, allowing for precise production based on models created in 3D design software. This ensures accurate and reliable manufacturing and allows clients to fully realize their ideas and design solutions.

- Allows to process profiles with measurements up to 1000 x 600 x 16 000 mm

- Drilling heads on 3 axes

- Shot blasting capability

OTHER PROFILE PROCESSING SERVICES

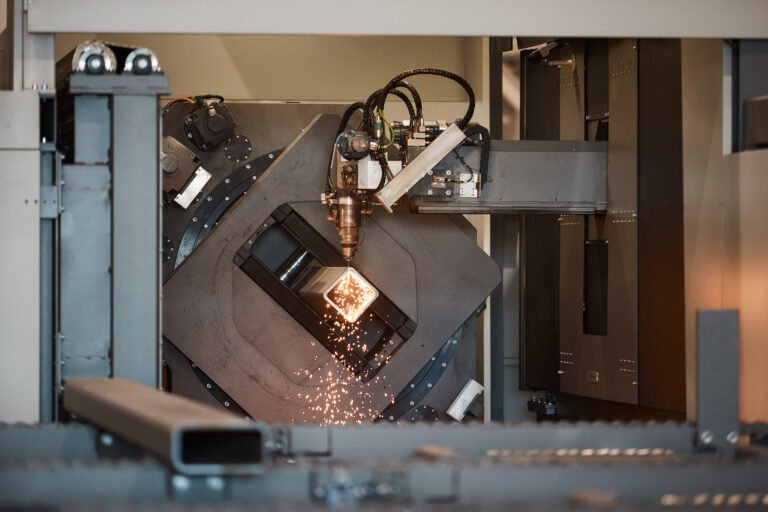

TUBE LASER

The tube laser serves the purpose of cutting and processing various tubes and profiles, offering numerous advantages to our construction and machinery industry clients.

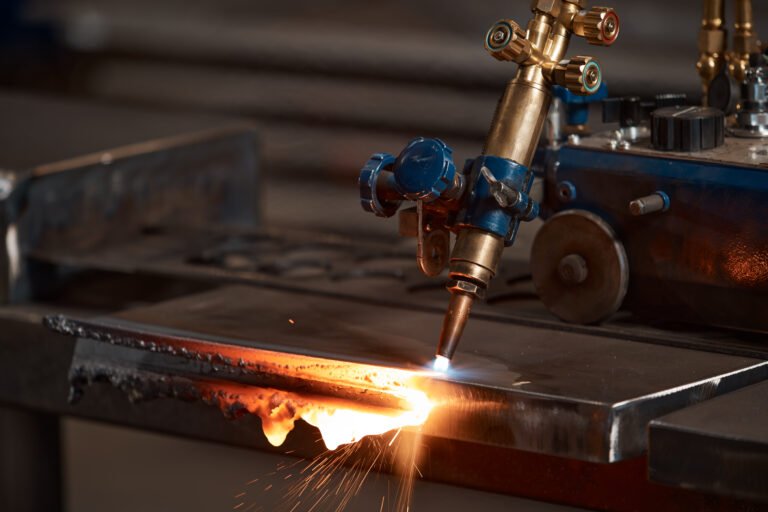

CHAMFERING

We perform chamfering according to the preparation requirements of both sheet metal parts and profiles. Proper chamfering of these parts ensures the quality, strength, and durability of the welds.

SHOT BLASTING

Shot blasting is a surface treatment process that removes rust, paint, or other impurities from metal and ensures surface roughness for subsequent processing or coating.

MARKING AND PACKAGING

Whether it's a large-scale construction project or complex manufacturing requirements, our marking services guarantee clear labeling for each product, simplifying production management seamlessly.

FEEL FREE TO CONTACT US!

JANAR VARBOLA

SALES TEAM LEADER FOR STEEL SERVICES

If you have a question, I have an answer! I help with all questions about sheet and profile processing. All inquiries will arrive in my mailbox, and I will answer them as soon as possible, but no later than two working days.