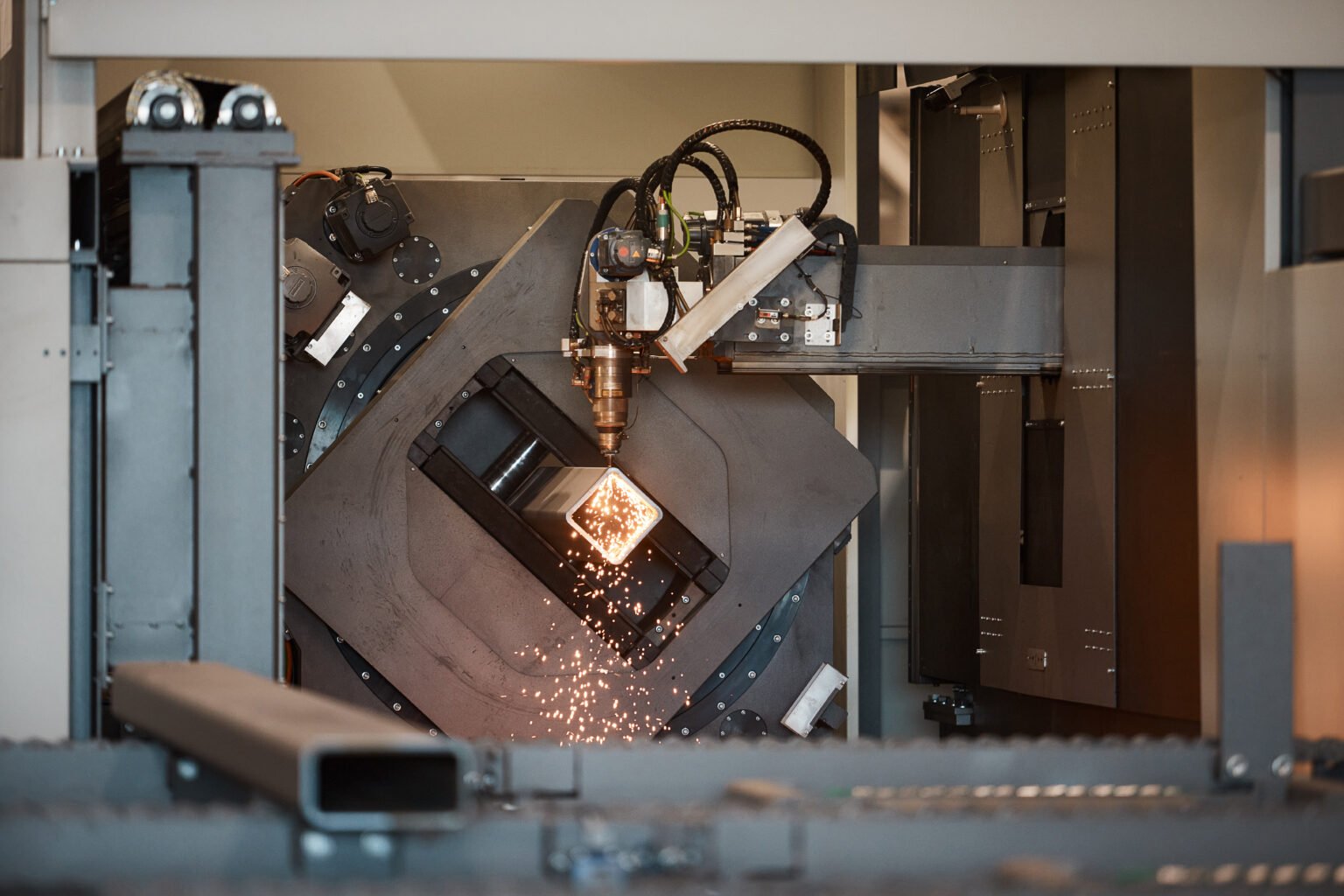

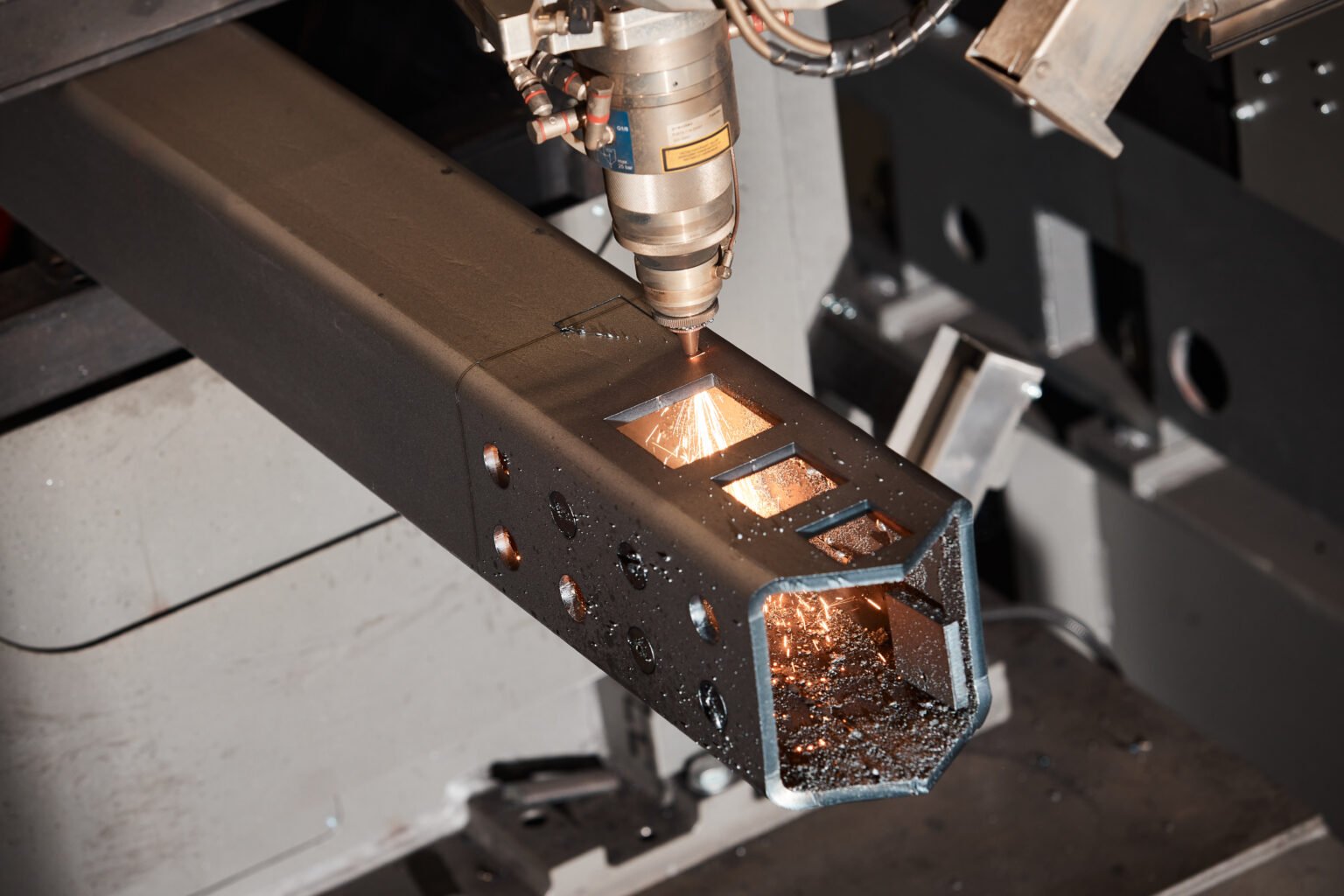

TUBE LASER

BLM LT24

The tube laser serves the purpose of cutting and processing various tubes and profiles, offering numerous advantages to our construction and machinery industry clients.

Equipped with a 4,5 kW laser, our machine excels in delivering high-speed and precise cuts on a variety of materials and profiles. Its 3D cutting capability enables intricate shapes and designs to be achieved with exceptional accuracy, a feat often challenging or impossible with traditional cutting methods.

In addition to cutting, our tube laser boasts drilling and threading capabilities, enhancing its versatility in processing profiles. This flexibility allows for seamless integration of additional features into the final product.

Capable of accommodating profiles up to 12,5 meters in length and with a maximum cutting width of 20 mm, our tube laser is suitable for a wide range of projects. It handles everything from the smallest components to cutting large structures.

- Maximum profile weight: 300 kg/m

- Maximum diameter of round tube: 610 mm

- Maximum size of square tube: 400 × 400 mm

- Maximum dimensions for beams: HEA 400, HEB 300, IPE 500, UPN 400

- Processing of profiles up to 12.5 m

- 3D cutting

- Thread tapping

- Drilling of holes

OTHER SHEET METAL PROCESSING SERVICES

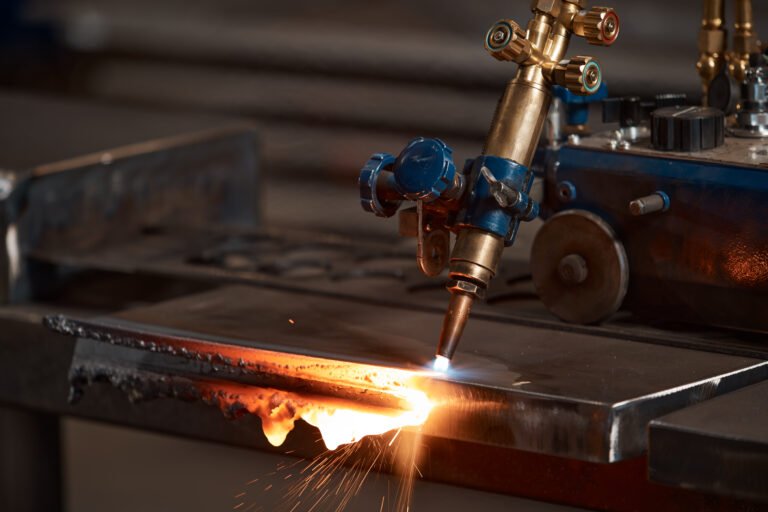

CNC PROFILE PROCESSING

The Kaltenbach profile processing machine offers several significant advantages to clients in the construction and machinery industries, including excellent cutting performance, precision, and cost savings.

CHAMFERING

We perform chamfering according to the preparation requirements of both sheet metal parts and profiles. Proper chamfering of these parts ensures the quality, strength, and durability of the welds.

Shot blasting

Shot blasting is a surface treatment process that removes rust, paint, or other impurities from metal and ensures surface roughness for subsequent processing or coating.

MARKING AND PACKAGING

Whether it's a large-scale construction project or complex manufacturing requirements, our marking services guarantee clear labeling for each product, simplifying production management seamlessly.

FEEL FREE TO CONTACT US!

JANAR VARBOLA

SALES TEAM LEADER FOR STEEL SERVICES

If you have a question, I have an answer! I help with all questions about sheet and profile processing. All inquiries will arrive in my mailbox, and I will answer them as soon as possible, but no later than two working days.